How to Ensure Your Disposable Bamboo Chopsticks Meet Food Safety Standards

- Share

- Issue Time

- Jul 15,2025

Summary

Discover comprehensive strategies to ensure your disposable bamboo chopsticks meet strict food safety standards. Learn about quality control, compliance and best practices with our QL experts.

In an increasingly health-conscious society, disposable bamboo chopsticks have become a must-have for restaurants, foodservice, and consumers seeking an eco-friendly dining experience. However, ensuring these products meet strict food safety standards is critical to protecting consumer health, maintaining brand reputation, and complying with international regulations. At QL, we are committed to helping manufacturers, distributors, and food service providers adhere to the highest safety standards through comprehensive quality assurance protocols, sustainable sourcing, and compliance with industry certifications.

This guide dives into the key steps required to produce, certify, and distribute food-safe disposable bamboo chopsticks that meet or exceed industry standards. From the selection of raw materials to final product testing, each stage is critical to protecting public health and enhancing consumer trust.

Understanding Food Safety Standards for Disposable Bamboo Chopsticks

Before exploring quality assurance practices, it is important to understand the food safety standards for the production of disposable bamboo chopsticks. These global and locally established regulations are designed to ensure that chopsticks are safe for direct contact with food. These regulations cover everything from raw material selection and production hygiene to chemical testing and product labeling. Compliance with these standards is critical to preventing contamination, protecting consumer health, and maintaining product trust.

Global Standards and Certifications

FDA (Food and Drug Administration): In the United States, disposable bamboo chopsticks must meet FDA guidelines for food contact materials. This includes ensuring that the chopsticks do not contain or release hazardous substances during use, such as heavy metals such as lead, cadmium, or other toxins. The materials must be non-reactive, odorless, and safe under normal use conditions.

EU Food Contact Regulations: In the EU, disposable chopsticks must meet the strict requirements of EU Regulation (EC) No 1935/2004, which regulates materials that come into contact with food. The regulation aims to ensure that substances in the chopsticks do not migrate into food in harmful amounts and that the chopstick materials do not change the taste, odor, or safety of food.

ISO Standards: The International Organization for Standardization (ISO) provides internationally recognized frameworks, such as ISO 22000, which specifies criteria for food safety management systems. The standards help manufacturers control food safety hazards at all stages of production and supply. ISO standards may also contain specific test methods for evaluating the structural integrity, antimicrobial, and chemical safety of bamboo chopsticks.

Together, these standards form the basis for producing bamboo chopsticks that are not only safe and reliable, but also meet the expectations of regulators and consumers around the world.

Local Regulatory Compliance

Depending on the market, additional local regulations may apply. For example, China's National Standard (GB), Japan's Food Sanitation Law, or India's Guidelines for Food Safety Standards and Certification Agencies (FSSAI) all specify safety parameters for bamboo and wood products intended for food contact.

Ensure safety by choosing food-grade bamboo

The safety and quality of disposable bamboo chopsticks begin with the careful selection of raw materials. Choosing the right bamboo is crucial because it directly affects the hygiene, strength, and compliance with food safety regulations. For manufacturers committed to producing safe and environmentally friendly chopsticks, it is crucial to give priority to sustainable, pollution-free, food-grade bamboo during the procurement process. This not only helps comply with regulations, but also enhances the trust of environmentally friendly consumers in the brand.

Raw Material Selection Criteria

Organic Sustainable Bamboo: Ideally, bamboo should be grown without the use of synthetic pesticides, herbicides, or chemical fertilizers. Organically grown bamboo minimizes the risk of chemical contamination and is in line with the global trend of sustainable, environmentally friendly procurement.

Maturity of bamboo: Mature bamboo is typically grown between 3 and 5 years old and has optimal strength, flexibility, and resistance to microbial growth. Using immature bamboo may reduce the durability of the chopsticks and increase their susceptibility to mold and pathogens.

Heavy metal and pesticide testing: Regular laboratory testing of soil and bamboo samples for potential contaminants such as lead, arsenic, cadmium, or pesticide residues is critical. These tests ensure that the final product is safe for food contact and meets FDA, EU, and other international safety standards.

Traceability: A transparent and traceable supply chain enhances quality control and increases buyer confidence. Detailed records—including where the bamboo was grown, how it was grown, the conditions under which it was harvested, and shipping logs—help ensure that each batch of chopsticks can be traced back to its source in the event of quality issues.

Supplier certification and audits

Working with certified and reputable bamboo suppliers is the cornerstone of a reliable sourcing strategy. Suppliers should hold the following internationally recognized certifications:

ISO 9001: Demonstrates a quality management system that ensures consistency and continuous improvement.

FSC (Forest Stewardship Council): confirms that bamboo comes from responsibly managed forests, providing environmental, social and economic benefits.

Sustainable forestry certification ensures long-term ecological balance and ethical sourcing practices.

Regular supplier audits are essential to verify compliance with food safety, environmental and social responsibility standards. These audits cover everything from bamboo harvesting techniques and sanitation practices to storage conditions and documentation processes.

By implementing strict raw material selection protocols and working with certified suppliers, manufacturers can ensure that their disposable bamboo chopsticks meet the highest standards of food safety, sustainability and consumer satisfaction.

Processing and Manufacturing Practices That Ensure Food Safety

Adherence to Good Manufacturing Practices (GMP) is essential to producing safe bamboo chopsticks. Each stage of the production process should be strictly controlled:

1. Cleaning and preparation

- Wash raw bamboo thoroughly to remove dirt, dust and surface contaminants

- Use food-safe cleaners that will not leave harmful residues

- Dry in a controlled environment to prevent microbial growth

2. Cutting and shaping

- Use sterilized equipment to prevent cross-contamination

- Implement automated cutting processes to ensure precision and reduce human contact

3. Heat treatment and sterilization

- Apply appropriate heat treatments (such as steaming at a specific temperature) to eliminate bacteria, mold and pests

- Use steam sterilization or hot air sterilization that meets food safety standards

4. Coating and finishing

- Use food-grade, non-toxic coatings to improve durability or appearance when necessary

- Avoid the use of chemical treatments that may leach into food

Conclusion: Enhance Your Brand with Safe and High-Quality Disposable Bamboo Chopsticks

Ensuring that your disposable bamboo chopsticks meet food safety standards is a multifaceted process that covers material selection, production procedures, rigorous testing and certification compliance. By partnering with QL, your business will receive high-quality certified bamboo, advanced production facilities, and a professional team committed to food safety excellence.

Taking comprehensive quality assurance measures not only protects consumer health, but also enhances brand reputation, cultivates customer loyalty, and establishes your business as a leader in sustainable and safe food and beverage solutions. An investment in strict compliance with food safety standards is an investment in long-term success and trust.

At QL, we specialize in custom bamboo food and beverage products, including bamboo cutlery sets, bamboo sticks, bamboo chopsticks, ice cream sticks, coffee stirrers, etc. We have 15 years of manufacturing experience, a skilled workforce (60% of whom have more than 8 years of professional experience), and a 42,000 square meter factory with a monthly shipment volume of more than 30 containers. Contact us and choose QL disposable bamboo cutlery, you will get unparalleled quality, safety and sustainability - because safety is not a choice; it is a standard.

Customizable, Renewable Resource, Strong and Sturdy, Heat Resistant, Non-Toxic, Smooth Finish, Natural Material

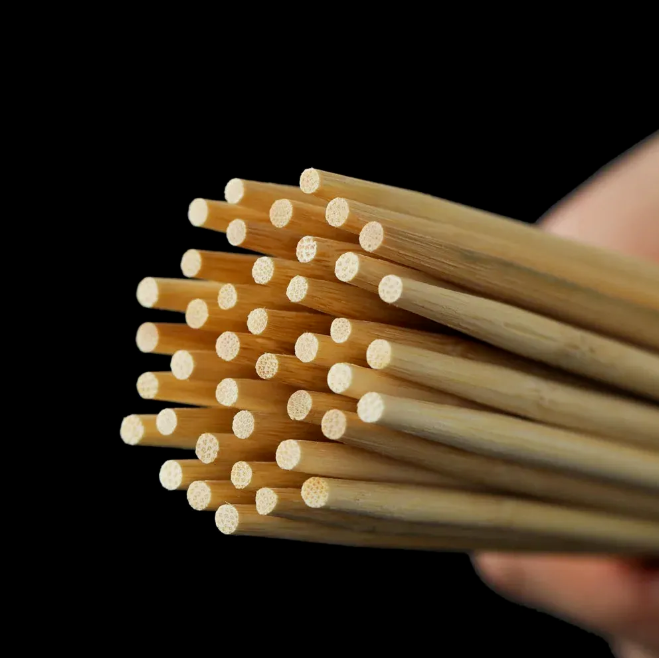

Disposable Bamboo Tensoge Chopsticks Natural Premium Custom Printing Paper Sleeve Wholesale Supplies

Nature & Smooth Bamboo Disposable Chopsticks are Safe & Durable Eco-friendly, Biodegradable, and Hygienic.

Splinter-Free, Safe and Durable, Premium Quality Round and separated Disposable Bamboo Chopsticks